Reliable Emergency Water Supply

Protect yourself - before disaster strikes

Get your emergency water today!

Protect yourself - before disaster strikes

At BLUE CAN Water in Los Angeles, CA, our mission is to provide long-lasting, great-tasting, emergency drinking water in aluminum cans. A better alternative to plastic water bottles, our canned water is purified using a state-of-the-art high-tech filtration system. BLUE CAN Water is sterilized and hermetically sealed in aluminum cans under pressure with nitrogen, allowing our premium emergency water to store safely for decades.

Have peace of mind knowing that your emergency drinking water has undergone proper water analysis and lab testing.

Our products are tested daily in-house and weekly by a certified laboratory. We stay in compliance with the California Health Department requirement of weekly E. coli and coliform testing. Turn to BLUE CAN Water for clean and safe emergency canned water supplies for storage.

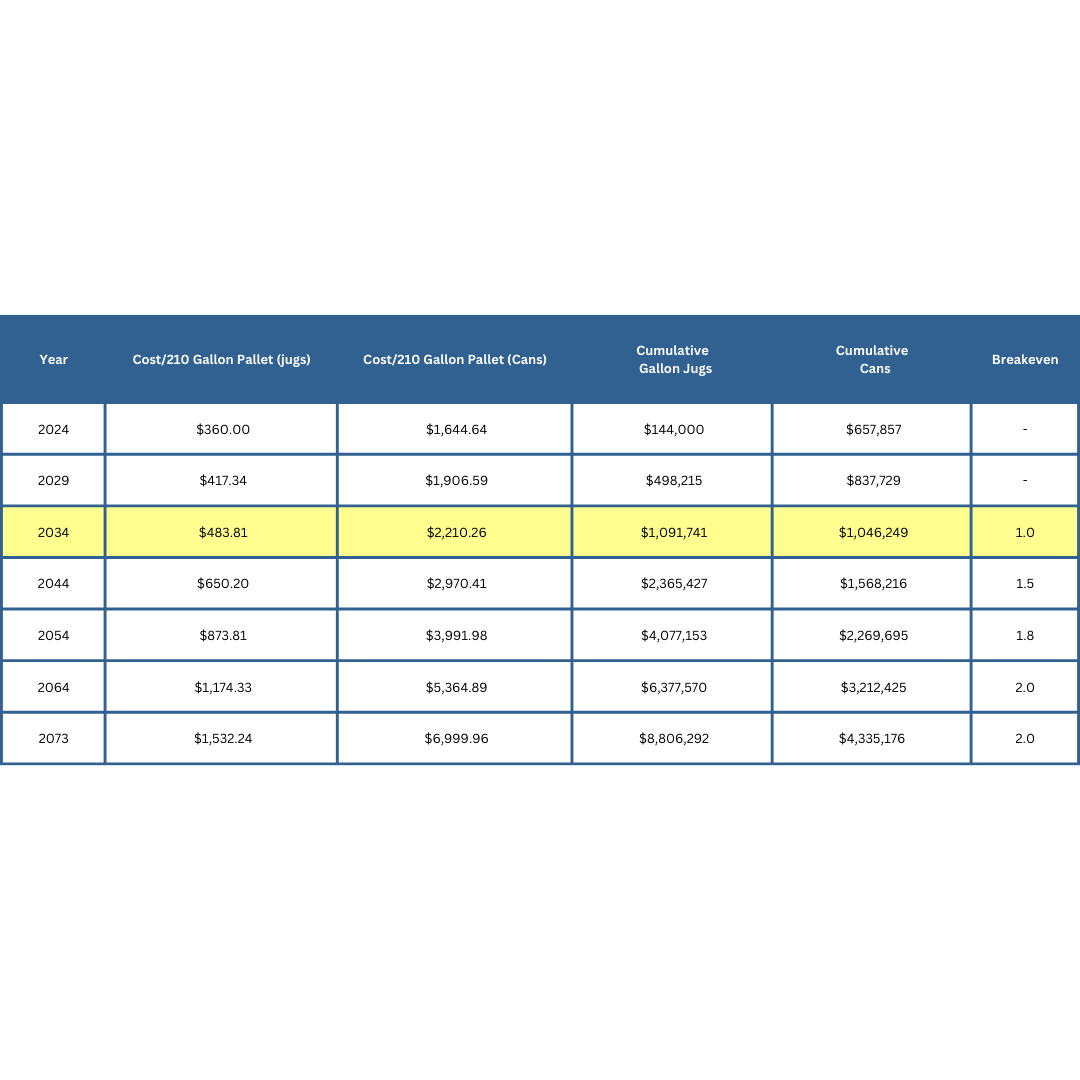

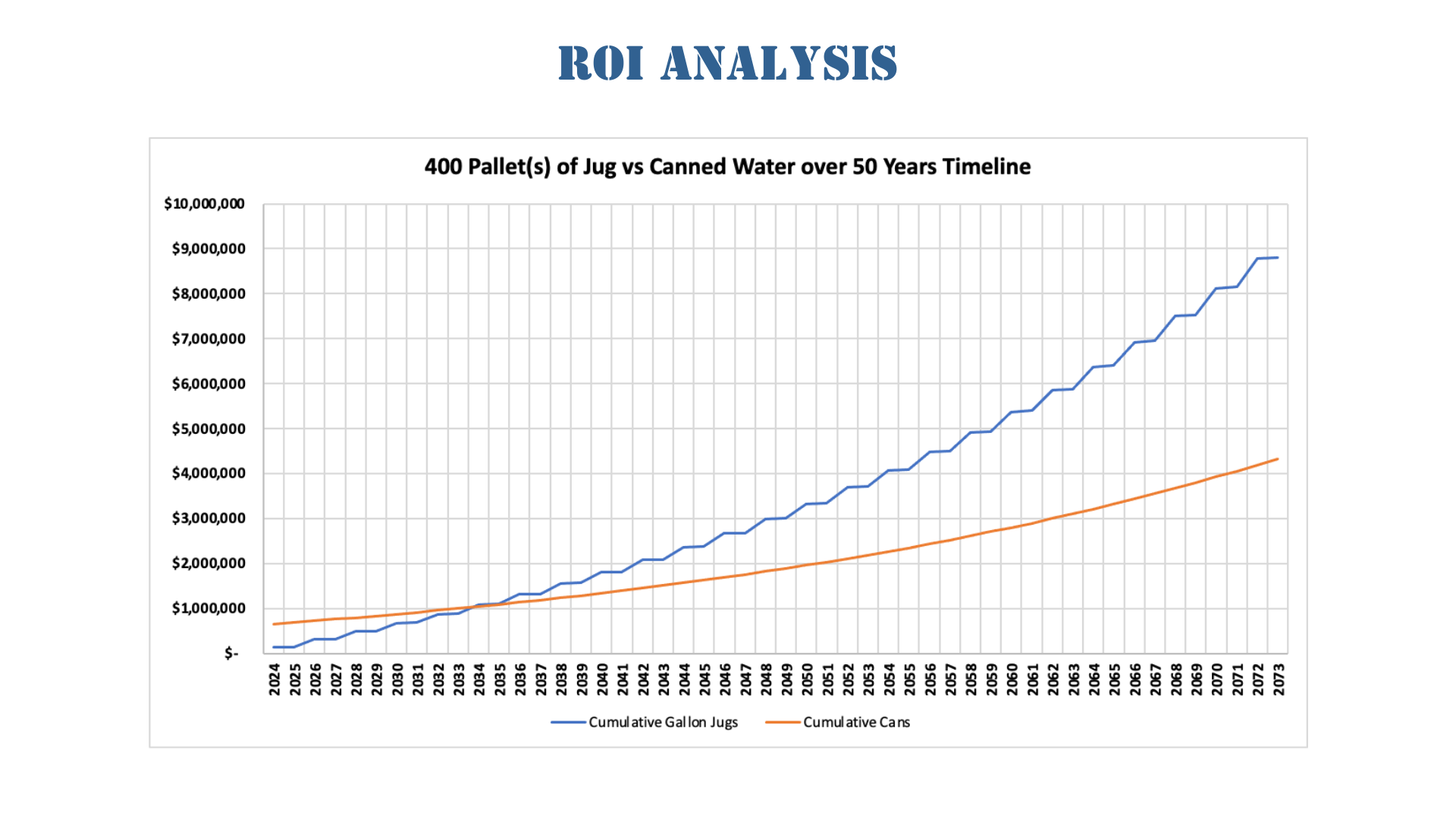

While the cost of plastic jugs continually increases, Blue Can Water not only becomes the cheaper option, but is better for the environment as well.

The return on investment is well worth the initial contribution.

Our canned water has a lab-certified 50-year shelf life; the only one on the market.

We use recyclable cans and packing materials, along with green, eco-friendly business practices.

Double stacked pallets save storage space by using a single pallet footprint.

Protect yourself - before disaster strikes.

Protect yourself - before disaster strikes.

Find the most frequently asked questions below.

BLUE CAN Water offers a 50-year shelf life guarantee for its water products based on state-of-the-art manufacturing processes that meet or exceed standard FDA regulations and bottled water industry standards. FDA has established specific regulations for bottled water in Title 21 of the Code of Federal Regulations (21 CFR) that you can read here.

The International Bottled Water Association (IBWA) further adds:

The U.S. Food and Drug Administration, which regulates the quality and safety of bottled water, has neither set nor suggested any limitation to the shelf life of bottled water. In that regard, the International Bottled Water Association’s general position is that as long as the water is packaged in accordance with FDA processing and good manufacturing practices, 21 CFR, Part 129, and meets the FDA quality standard provisions as outlined in 21 CFR, Part 165, the product’s shelf life should remain intact for an indefinite period provided that product storage is as recommended by the manufacturer.

BLUE CAN Water is purified, disinfected, and sterilized to remove any chemicals or particles using a 12-step multi-stage process. This process includes using active charcoal filters, dual reserve osmosis under high pressure, six-stage micron traps, two sterilizers, high-intensity UV lights, active pH balance, and ozone sterilization with state-of-the-art technology, all preserved under pressure.

Temperature fluctuations do not change the quality of our water. It’s recommended water be stored between 38 degrees F (2 degrees C) and no higher than 145 degrees (55 degrees C) F for best results.

BLUE CAN Water has an ORP of approx. 430, according to the FDA Certified Lab. Deionization is not required.

In accordance with the FDA requirements and California Proposition 65, BLUE CAN Water cans have a non-BPA epoxy coating on the inside to protect the contents from the metal. (Aged water in the can have been tested BPA-free by an FDA-certified lab.)

Radiological testing is done every year, and no radiological residue has been detected. Water analysis reports are performed by third-party laboratories using procedures established by EPA, AOAC, APHA, AWW, and WPCF. Extensive testing was conducted by an independent analytical NELAP-accredited laboratory (Weck Laboratories Inc. ISO 17025, ELAP #1132, LACSD #10143, NELAC #04229CA) that certified that the test results meet all requirements of NELAC. According to the certified lab report, BLUE CAN Water meets all drinking water standards as established by the State of California Department of Health Services. The certificate of analysis is available here.

Click here to view our Limited Warranty.

Our unique manufacturing process allows water to be hermetically sealed and safely stored for 50 years.

Fifty years if stored properly.

No. The water does not have a metallic taste at all. There is a non-BPA epoxy coating inside the can and on both sides of the lid to protect the water from the aluminum.

Yes. It’s lab-certified, BPA-free water tested in the can. Click here to review our Water Report 2017.

Yes. Heat changes have been lab-tested and do not affect the water inside.

Our water is filtered by the latest in modern technology, multi-stage filtering and purification system to ensure the cleanest water possible.

Aluminum is the ideal container for long-term shelf life. In beverage cans, it can be hermetically sealed (nothing can go in and nothing can go out) it has strength for stacking pallets, and aluminum also never rusts (there is no iron in aluminum to allow rusting). Aluminum is a sustainable metal and can be recycled over and over again. A can is generally turned into a new can and back on store shelves within 60 days. Cans are usually available through curbside pickup or community drop-off locations worldwide.

Drain all liquid from the cans and bag or box. The cans do not need to be crushed.

Check your cans with a magnet. A magnet will not be attracted to aluminum. Aluminum cans are also much lighter than steel cans, and aluminum will not rust.

Aluminum cans, by far, not plastic or glass. The recycling of cans outpaced the recycling of all other containers. Aluminum cans lead the way with a recycling rate of 65%. Recycling pays and is a win-win for the environment and a sustainable society. Most plastic is not recycled; of collected plastic bottles. less than 9% is actually recycled into new products. All aluminum cans are recyclable.

The closed-loop recycling process represents recycling at its finest, remanufacturing a product back into the same product, like an aluminum beverage can which can be recycled into a new aluminum beverage endlessly. Plastic is an open loop. Recycled plastic cannot be used to make new plastic bottles; the plastic is contaminated. So, a new plastic bottle is made of 0% recycled plastic. A new aluminum can is made up of an average of 45-70% recycled aluminum.

Recycling one aluminum beverage can save enough electricity to power a TV for three hours or a 100-watt light bulb for four hours. Recycling 40 aluminum beverage cans have the energy-saving equivalent of one gallon of gasoline. It takes 95% less energy to recycle aluminum than to start at the beginning mining the bauxite. Recycling that beverage can reduce effluents and emissions by 95%, creating a more sustainable future.

Use this text to share the answer to the question with your customers.

Clicquot Club ginger ale was the first canned soft drink, debuted in 1938. Delivering the soda was a cone top can produced by Continental Can Company. Design improvements continued, and in 1948, Continental Can and Pepsi-Cola launched the first major rollout of soft drinks in cans. The can carried 12 oz of refreshment and was sold for ten cents.

Tin cans have been replaced by tin-free steel, which is given a thin tin coating, usually as thin as human hair, to prevent rusting. Protective coatings applied to the inside of the cans ensure the integrity of the contents and have allowed cans to hold many products, such as acidic fruits, which would otherwise be too corrosive. Technologies for both tin-free steel and aluminum have added even more flexibility and versatility to today’s can.

There are approximately 2,000 certified recycling centers in California. Call 1-800-RECYCLE or visit our online recycling center locator to find the certified recycling center nearest you.

In addition to a certified recycling center, consumers can donate recyclables to a community service program, a drop-off or collection program, or a curbside recycling program. As with recycling centers, these programs are operated by independent businesses or local governments, not the State of California.

Currently, state-certified recycling centers pay a minimum of $1.570 CRV for aluminum cans; $1.000 CRV for clear PET plastic bottles; $0.570 CRV for HDPE plastic bottles (similar to the large water jugs); and $0.105 CRV for glass bottles. These per-pound CRV rates fluctuate annually usually taking effect on the first day of the year. In addition to the CRV, recyclers may also pay a scrap value, which may also fluctuate.

Yes, if the material is contaminated. Operators of certified recycling centers must inspect each load of containers to determine whether it is eligible for CRV. Recycling centers have the option to refuse to accept containers that, in their opinion, are excessively contaminated with dirt, moisture, or other foreign substances. Alternatively, recycling centers may adjust downward the CRV per pound used to calculate the payment by the ratio of such substances to empty beverage containers. In this circumstance, the consumer has the right to accept the discounted refund and/or scrap price, to separate refund from no refund material, or to take the material back.

Certified recycling centers are not official “weigh masters.” However, they are required to weigh materials that have been presented for redemption on a scale or other device that has been properly approved, tested, and sealed by the local county department of weights and measures. During inspections and onsite visits, CalRecycle personnel verifies that recyclers’ scales bear proper seals. It is unlawful, and punishable as a misdemeanor, for any person to use for commercial purposes a scale that is “incorrect.” Suspected violations should be referred to the appropriate county department of weights and measures, which is ultimately responsible for ensuring the accuracy of recycling center scales.

Typically, recyclers “zero” their scales with the bucket on them prior to weighing redeemed materials. Alternatively, recyclers may mark the outside of each bucket with its weight, then deduct that weight from the scale measurement.

Generally, no. However, requirements about the condition of beverage containers are established by the recycling center and may vary from one recycler to the next. Therefore, you should contact the recycling center where you plan to take your containers to determine their requirements.

No. The owners and employees of recycling centers are not State employees. CalRecycle is responsible for certifying recycling centers to participate in the program. This certification does not confer any “state” employment status.

Reviews

Your cart is currently empty.